Applications

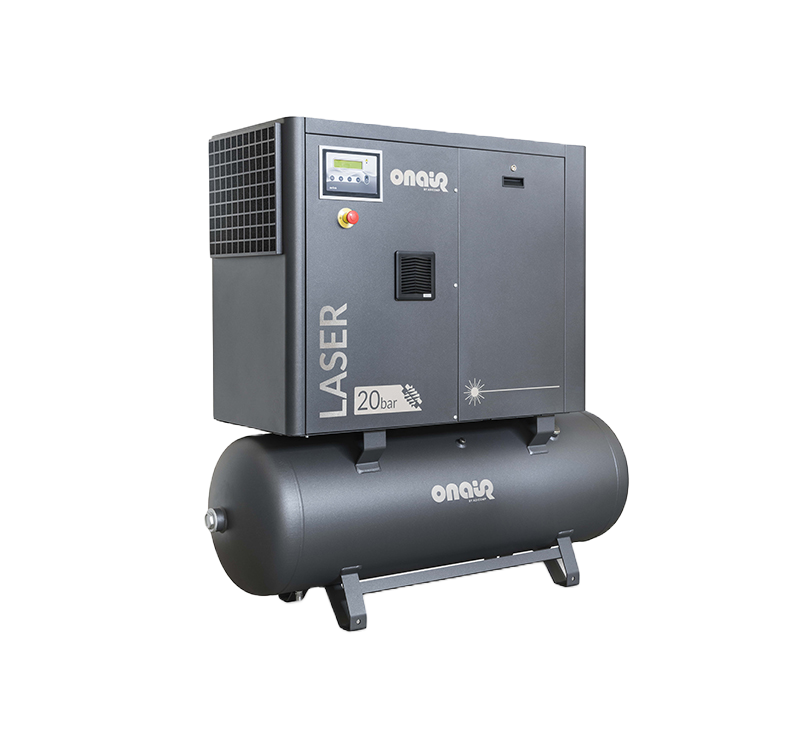

The LASER series compression units are designed for intensive use, and are known for their high efficiency. Compact and quiet, they have been specifically designed for laser cutting industrial environments, which therefore require air flow rates at high operating pressures.

Use of the LASER series Onair systems therefore allows to cut by air, thus avoiding the use of nitrogen and considerably saving money

fully designed and made in Italy, the last generation screw compression units of our parent company Termomeccanica are capable of reaching pressures up to 20 bar.

This particularity allows LASER compressors to be extremely versatile and suited to all compressed air requirements at different operating pressures.